The production department is the core of any manufacturing company. Therefore, efficiency and communication are crucial in this area. What challenges do you encounter in production, and how do you maximize the performance of your production department?

Common challenges in production

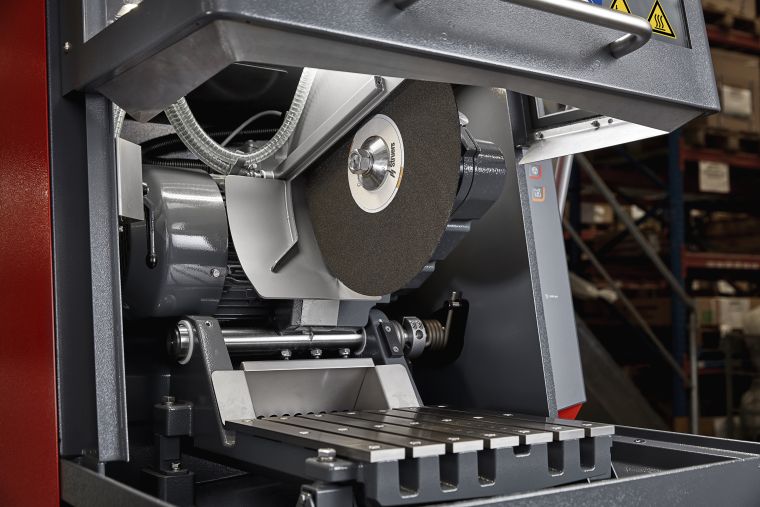

The manufacturing department significantly influences a company’s ability to differentiate its products. Consequently, this department plays a crucial role, but often faces challenges that undermine its effectiveness. Such as, the rising energy costs and the demand for more sustainable production methods. Think of adjusting the production planning to peak consumption, reducing emissions and waste, and selecting sustainable suppliers.

Below are some additional common challenges:

A lack of visibility into the production process and order status can lead to inefficiency and increased costs.

Poor integration and reliance on manual processes hinder real-time access to accurate information.

Without robust production planning, companies cannot efficiently utilize resources such as staff, machines, and materials, resulting in waste and higher operational costs.

Increasing customer demands lead to more complex products and production methods.

Efficient production requires sharing and making information available outside the production department, such as product designs, parts lists, and inventory. Often, the production department lacks sufficient insight into these areas.

Limited visibility into the production process can result in quality problems. Detecting and preventing these issues in a timely manner is often challenging.

Objectives of every production department

Do you recognize the above challenges? If so, it is likely that your production department is not operating at its full potential and there is room for improvement.

To optimize your production department, it is advisable to define clear objectives. This approach will transform your department into a well-oiled machine. Below are some key objectives that every production department should strive to achieve:

✓ Master data quality: This

is crucial for any production company. Without the necessary quality in master

data, poor decisions and numerous operational errors occur daily.

✓ More efficient production process: By

utilizing resources such as labour, machines, and materials more efficiently,

you can increase productivity within the department and reduce energy

consumption and waste.

✓ Higher product quality: Customer

satisfaction is paramount in every industry, and product quality plays a

critical role in this. Therefore, it is essential to continuously measure and

optimize the quality of your products and production processes.

✓ Faster delivery: Delivery time is another

crucial factor for customers. It is vital for production departments to

establish a well-thought-out production plan that ensures timely delivery but

still remains flexible and agile in case of unplanned activities.

✓ Cost reduction: By improving both process

and product quality and improving efficiency by better utilizing resources, you

will simultaneously reduce costs.

✓ Visibility in the production process: To

achieve the above objectives, it is advisable to enhance visibility in your

production process. This can be accomplished by digitizing processes, capturing

data from your machines and creating real-time insights from the shop floor.

By implementing the right technological solutions within your production department and allowing data to flow across the various departments of your company, you can achieve the above objectives.

It is essential that your production department collaborates with other departments - discover why:

While the production department can optimize its own processes, it is also essential to keep in mind, that maximizing production efficiency requires seamless connections between relevant departments. Data should flow through your company as a digital common thread to enhance collaboration and productivity.

A key link to the production department is engineering and R&D. Product designs and Bills of Materials are created there and then passed on to production. Manual work and inefficient processes hinder effectiveness and often reduce master-data quality.

Together with the inventory and purchasing departments it’s also crucial to ensure clarity on parts availability and timing. Delivery deadlines and the progress of the supply chain are vital for effective production planning.

Providing comprehensive support to the finance department in optimizing working capital is essential in today’s operations. Key performance indicators such as optimizing stock levels, reducing production time and scrap, among others, are critical for manufacturing companies to thrive in the evolving global landscape.

On the one hand, communication and feedback from the service department regarding delivered products is valuable to production. On the other hand, the service department benefits from insights into production data.

Discover our customer stories

We are happy to assist you with your production solution

Whether you're considering optimizing your production department, already working with production software and needing support, or wanting to discuss how to get even more out of your existing production solution, we are here to help you.